Factory SDN project for a domestic automobile manufacturing customer

Delivery Project

Customer Profile

As a leading global supplier of automotive seats, the company's business areas cover seat assemblies, mechanical parts, seat foam, seat covers, headrests and roof systems.

Customer Requirement

This factory construction is for the support of Li Auto. The factory covers an area of 90,000 square meters. The aim is to strengthen its vertical integration strategy and accelerate business development. It requires the overall construction of the IT network project, which includes network coverage devices for buildings such as the joint factory 1, the joint factory 2, the comprehensive building, and the gatehouse.

Solution

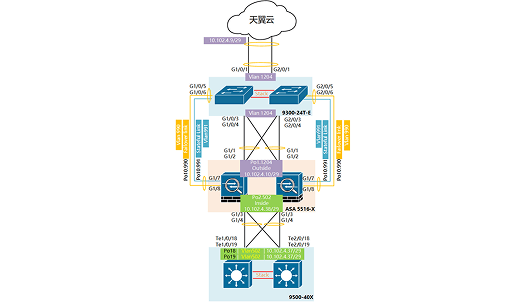

- The factory fabric technology that supports the SD-Access architecture enables the use of a virtual network (overlay) running on the physical network (underlay) to create alternative topologies for connecting devices.

- The network is divided into two architectures: one is a DNA-driven software-defined network architecture (covering the wired part of the joint factory building 1), and the other is an architecture reserved for the office area network that can be expanded to a software-defined network.

- Key network control plane nodes, wireless management nodes, and Internet edge nodes all adopt HA architecture to improve business reliability.

Customer Benefits

Built a flexible, secure, efficient and scalable intelligent network infrastructure;

Significantly improve production efficiency and operational agility, while laying a solid foundation for future Industry 4.0 upgrades, helping companies achieve cost reduction, efficiency improvement, and long-term competitiveness enhancement.