Smart factory network for automotive seating system suppliers

Delivery Project

Customer Profile

The client is a leading global automotive seating systems supplier, specializing in the R&D and manufacturing of intelligent cockpit solutions, with operations spanning major automotive markets worldwide. With dozens of production bases in China and overseas, the client leverages its technological innovation and lean manufacturing capabilities to provide long-term service to renowned international vehicle manufacturers.

Customer Requirement

This project is a supporting construction project for the Wenjie Chongqing Super Factory. The client hopes to build an intelligent network system covering the entire production process through this network intelligent information construction, realize equipment interconnection and real-time data collection and analysis, eliminate information silos to improve production efficiency and quality control accuracy; at the same time, deploy a unified production execution, material traceability and equipment operation and maintenance platform to support dynamic scheduling, process parameter optimization and remote diagnosis functions to reduce manual intervention; the network architecture needs to be compatible with future automated production lines and intelligent equipment (such as AGVs and robots) to meet the adaptation requirements of new energy vehicle seats for high-precision, multi-variety mixed-line production;

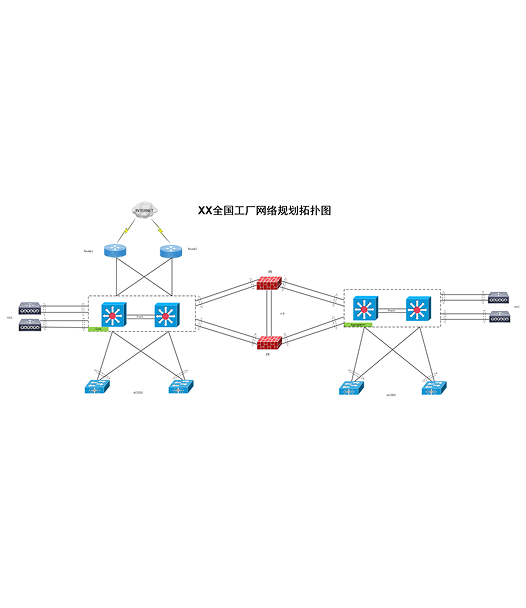

Solution

- Key network exit, core switch, and wireless controller nodes all adopt HA design

- The production area and office area are isolated through firewalls, and detailed strategies are implemented to ensure security within the production line.

- The production firewall device serves as the gateway device for the entire production environment, and traffic is controlled by the firewall in different areas.

- Achieve full network coverage within the production line, plan AP distribution based on the actual environment of each factory workshop and key coverage areas, ensure network stability of terminal equipment in the workshop, and protect AGV

Customer Benefits

Through HA redundancy, secure isolation, global interconnection, and intelligent design, the reliability, security, and scalability of the customer's nationwide factory network have been significantly improved;

Support its global production needs and business growth, reduce operation and maintenance costs, and provide a reliable infrastructure for future digital transformation.